Effective Material Modification: Three-dimensional Control of Molecular Click Reactions

-

Author:

Tatjana Erkert

- Date: 06.07.2012

Effective Material Modification:

Three-dimensional Control of Molecular Click Reactions

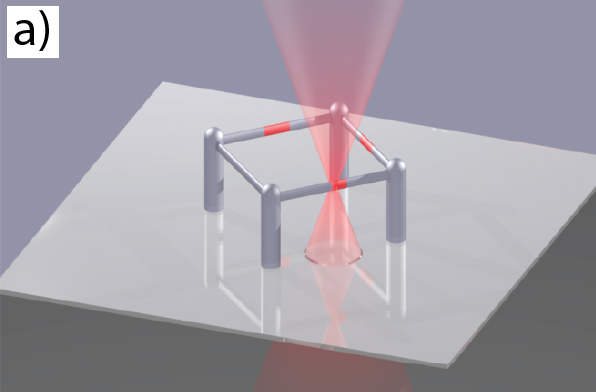

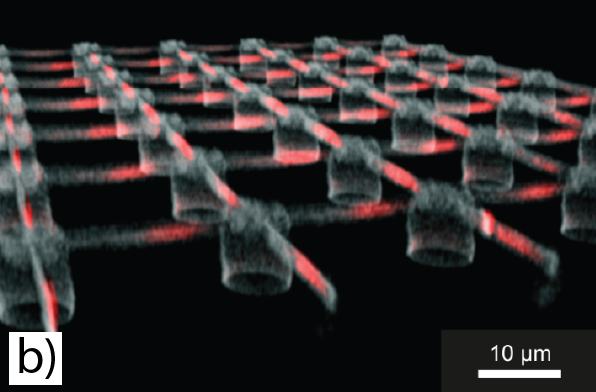

a) 3D polymer framework is functionalized at exactly defined locations with the help of laser light. (Schematic representation)

(Figures: Benjamin Richter)

CFN Congratulates Thomas Paulöhrl on the 2012 Lanxess Talent Award

The 2012 Lanxess Talent Award in the amount of EUR 4000 in the category of “Advances in Polymer Materials” goes to KIT polymer chemist Thomas Paulöhrl. With this new award Lanxess, a speciality chemicals group, honors young scientists for excellent work in the early phase of their academic career. For his Ph. D. thesis, Paulöhrl generated various surface structures and three-dimensional frameworks by means of light-induced click strategies. In this way, material can be modified efficiently and with nanometer precision.

In recent years, the interest in click reactions for effective material modification has increased significantly. Specifically assembled polymer surface patterns have a number of applications, for instance in tissue cultivation, cell biology, and medicine.

The concept of click chemistry goes back to the American chemist Barry Sharpless, who was the first to define this term in 2001. Complex molecular structures are first produced as partial rather than complete structures. During the subsequent reaction, these structures “click” together rapidly, similar to a peg game. Meanwhile, many of these molecular components have been described where clicking is spatially and temporally uncontrolled. However, non-controlled clicking is not sufficient for the manufacture of surface structures and three-dimensional frameworks.

In his Ph. D. thesis under the supervision of Professor Christopher Barner-Kowollik, Paulöhrl develops various chemical strategies for the production of three-dimensional surfaces by means of highly efficient spatially and temporally controlled click reactions. His trick: An exactly defined micrometer-scaled polymer basic framework to which biomolecules, activated by a second laser, click in a spatially predetermined manner.

The basic framework is the result of the interdisciplinary cooperation at the DFG Center for Functional Nanostructures (CFN). Paulöhrl used the 3D laser lithography method developed by Professor Martin Wegener and worked together with Ph. D. student Benjamin Richter from the group of Professor Martin Bastmeyer. This group has already explored the potential of this novel type of cell framework.

As a result, the molecules are fixed and their spatial position is influenced. Paulöhrl used photo-activable biomolecules, where the spatially resolved attachment process is triggered via light. As a result, nanometer-scaled material structures of biomarkers are produced. These biomarker frameworks are used among others for studying stem cell differentiation.

Paulöhrl is presently carrying out his doctorate at the Institute for Chemical Technology and Polymer Chemistry of Karlsruhe Institute of Technology (KIT) under the supervision of Barner-Kowollik. The research work was co-funded by CFN. Some of the results will be published in the journal: “Angewandte Chemie” International Edition DOI: 10.1002/ange.201107095.*

*

Pauloehrl, T.; Delaittre, G.; Winkler V.; Welle, A.; Bruns, M.; Börner, H. G.; Greiner, A. M.; Bastmeyer, M.; Barner-Kowollik C.; Adding Spatial Control to Click Chemistry: Light-Triggered Diels–Alder Surface (Bio)functionalization at Ambient Temperature, Angew. Chem. Int. Ed. 2012, 51, 1071–1074.

The 2012 Lanxess Award

Lanxess Deutschland GmbH is a specialty chemicals group focusing on polymer chemistry. The 2012 Lanxess Talent Award in the amount of EUR 4000 in the categories of “Advances in Polymer Materials” and “Innovations in Process Engineering” is granted for the first time this year. The candidates are proposed by their university teachers. Of more than 30 nominees, ten young chemists and engineers were given the opportunity to present their research work at the first Summer School of the Research Institute for Interactive Materials at Aachen University (RWTH). An expert jury of RWTH and Lanxess Deutschland GmbH staff selected both laureates. The group specialized in polymers and is a partner of the Summer School. The award has been donated by Lanxess to support interdisciplinary research in the field of polymer sciences.

“The Lanxess Talent Award is intended to reflect the growing relevance of this field of research and be an incentive for young scientists to get involved in the pertinent projects,” says Dr. Werner Breuers, Member of the Board of Management of Lanxess AG. (Link zur PI der RWTH). Breuers is responsible for “Performance Polymers, Innovation & Technology” and graduated at Aachen Technical University.